|

|

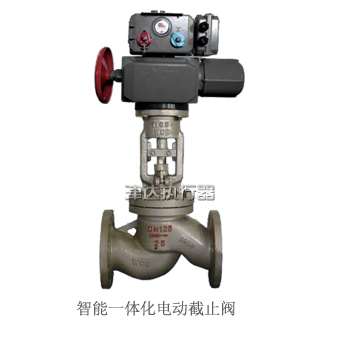

Electric check valve Belonging to forced sealing type valve, the electric check valve is connected with the actuator and complete the task of adjustment through receiving 1 ~ 5V intermittent contact control signal transmitted by the system or computer. When closing the valve, the pressure must be exerted to valve clack in order to avoid leakage of the forced sealing surface. Meanwhile, this type of valve is also more tightly under the action of this medium. It has the features of reliable seal, high hardness, wear resistance, high temperature resistance, corrosion resistance, abrasion resistance and long performance life. Thus it is suitable for the thermal power plant, petrochemical industry and metallurgy industry.

|

Main Technical Parameters

|

Nominal diameters DN(mm) |

40、50、65、80、100、125、150、175、200 |

||

|

Nominal pressure PN (MPa) |

1.6、2.5、4.0、6.4、10.0、16.0 |

||

|

Materials of valve body |

ZG230-450WCB |

ZG1Cr18Ni9 |

ZG1Cr19Ni12Mo2 |

|

Operating temperature t (℃) |

-29~425 |

-29~500 |

-29~500 |

|

Suitable media |

Water, steam, oil products, nitric acid, acetic acid, oxidizing medium, etc. |

||

|

Connection type |

Flange mode, threaded connection and welded connection |

||

|

※ Optional electric actuators |

Integral type, switching value, remote control type, explosion-proof type, integral adjustable type, split control type, etc. (Please refer to the information of actuator for specific option) |

||

|

※ Voltage of power supply |

Domestic Standard: 220V +10-15% ~ 380V +10-10% (50Hz ± 1Hz, linear power supply) Exported product can be customized: 110V ~ 480V (50Hz ~ 60Hz) |

||

|

※ Level of protection |

IP55~IP68 |

||

|

※ Explosion-proof mark |

Exd II BT4 |

||

|

Operation environment |

Environmental temperature -10 ~ 70℃Humidity ≤ 95% No condensation Avoid corrosive gases in the air | ||

※ some products can be selected according to conditions on site, if have any doubt, please contact our company.